Ball and globe valves are two kinds of valves used in various applications. A wide range of industries and applications utilize both varieties of valves. How can one determine which form of valve best suits their requirements? It is critical to select the appropriate valve for the operation. This blog will explain the crucial distinction between a globe valve and a ball valve by comparing the two.

Ball Valve Vs. Globe Valve: Working Principles

Ball valve working principle

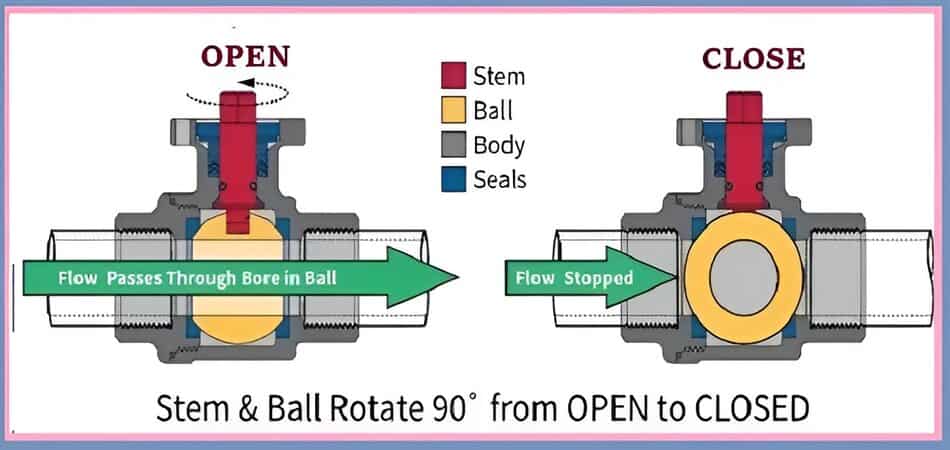

A quarter-turn and a quarter-turn ball valve can be opened or closed with a 90° rotation of the handle. The stem and the ball are connected. A closure is formed when the ball rests on the seat of the ball valve. Stem gaskets with O-rings are utilized to prevent leakage. Each of these elements is contained within the valve housing. A bore flows through the ball.

When functioning normally, the bore is either perpendicular to the apertures of the valve, which obstructs flow, or aligned with them to permit flow.

Globe valve working principle

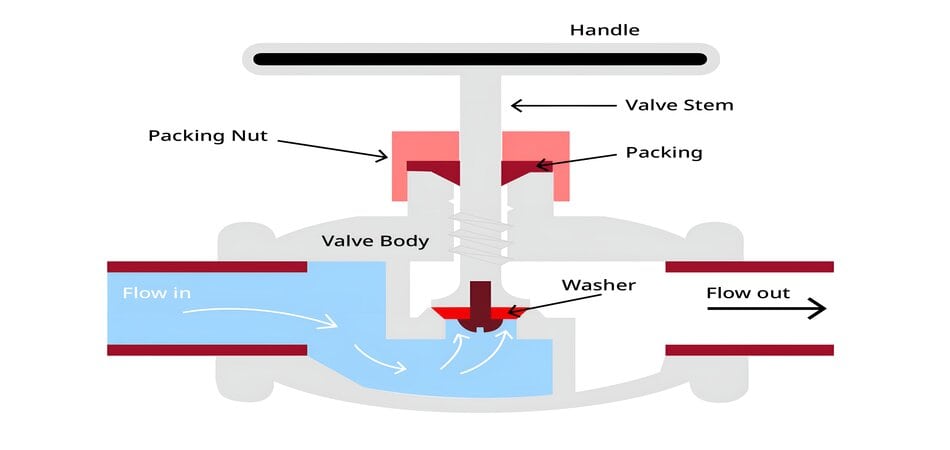

As a globe valve is a multi-turn valve, turning the handwheel in either direction requires more than 360° additional rotations to complete the operation. Valves, bonnets, handwheels, stems, and plugs are the principal components of globe valves. The media enters the valve body via the inlet and exits via the outlet. The bonnet safeguards the threaded components from the same material as the valve body.

When the handwheel is rotated, the threaded stem rotates, causing the plug to ascend or descend. Raising the plug widens the orifice, permitting the passage of media. Lowering the stopper into the valve seat closes the orifice, obstructing the flow.

On the other hand, elevating the disc increases the flow rate. At its utmost elevation, the disc generates the most significant flow rate. Angling the disc proportionally through the stem regulates the fluid flow rate.

Globe Valve Vs Ball Valve: What Is the Difference

There is a massive difference between the globe valve and the ball valve. These two parts of the linear valve group would be found in the pipe systems. What would you do with these two? Take a look at the globe valve vs ball valve.

Structure

The visual distinction between globe and ball valves is the primary one. Various classifications of ball valves are possible based on the housing structure, ball design, and port size. Ball valves may consist of one, two, or three pieces depending on the enclosure’s structure.

Ball valves are classified as full port, standard port, and reduced port based on the size of the port. Additionally, based on the number of ports, ball valves are categorized as two-way or multiport.

Numerous globe valve components are contained within the cavity. The globe valve’s design allows for obstructions that help it achieve its primary function of regulating and providing a preferable closure. Flow modifications permitted by this design may contribute to high-pressure reductions. The globe’s stem is rising.

Pressure and Temperature Ratings

Due to their inflexible metal-to-metal sealing mechanism, ball valves can withstand more significant pressure and temperature ratings than globe valves. Gas or vacuum systems are additional applications that make them suitable for “bubble-tight” termination requirements. In contrast, the easier seating material of globe valves makes them more susceptible to deterioration over time. As a result, their use in extremely high-pressure systems is not recommended.

Flow Control

A ball or globe valve may be turned on or off to modify the flow. However, globe valves may also work in a condition that is either partly open or closed to modify the flow. Having the disc of the globe valve lie in parallel to the flow allows for this flow control to be achieved. The linear flow rate that globe valves can attain is much greater than that of ball valves. Additionally, globe valves can lessen the impacts of water hammer.

Function

The gate valve is not meant to regulate flow; rather, it is intended to keep media from coming into contact with them. It is not the purpose of the gate valve to be able to bear the force of media flowing in positions that are only partly open. When managing the media flow, the globe valve has a significant capability.

Compatibility of the Materials

Stainless steel, brass, or bronze are frequently used to produce ball valves. These materials are worn and resistant to corrosion and high-temperature conditions. On the other hand, the housing, plug, and seat of globe valves may be made out of various materials, and the choice of these materials should be carefully considered by the fluid being regulated.

Because it requires less maintenance and has a longer lifetime, a ball valve may be more cost-effective than other valves, depending on the application. On the other hand, globe valves have a greater initial cost and are often designated for applications that need precise flow control. Globe valves are used in a variety of applications.

Applications

A spherical closure element that engages with a seat in the valve’s body distinguishes ball valves. Conversely, a disk-shaped closure element forms a seal against a receptacle within the body of a Globe valve. Because of their distinct configuration, ball valves are more suitable for use in situations requiring a quick flow stop, such as emergency shut-off systems. However, in situations where a modulating action is necessary, such as when controlling the flow of a process fluid, globe valves are more suitable.

Head Loss

The pressure loss (head loss) in globe valves’ completely open position is substantially more than in ball valves. As the fluid travels through a globe valve, it must reverse its flow several times, which is why this phenomenon occurs.

Globe Valve and Ball Valve Similarities

Ball valves and globe valves are similar in some ways. Both valves are used in pipe systems to control the flow of gases and liquids. In a pipe, both are shut-off valves meant to allow or restrict fluid passage. Ball valves and globe valves can be operated either manually or mechanically.

Are Ball Valves Better Than Globe Valves?

It’s natural to wonder whether ball or globe valves are superior. This question has been discussed for years. So, it’s important to acknowledge that each type of valve has benefits and drawbacks. There is no universal agreement over which form of valve is superior. Your specific application needs and requirements should be the ultimate deciding factor.

Ball valves are well-known for their longevity and resistance to high temperatures. They are also not too difficult to install or maintain. However, they are not as simple to regulate as globe valves and may be rather noisy when operating.

On the other hand, globe valves are well-known for their accuracy and the ease with which they may be controlled. In addition, they are far less noisy than ball valves and may be used in various contexts. However, they may be more challenging to install and maintain than ball valves, and they may not have the same level of durability.

A tight seal is required in many applications, such as pipelines that convey hazardous compounds. Therefore, globe valves are frequently used for these kinds of applications. In addition to this, they are suitable for use in high-pressure situations. On the other hand, ball valves are often used when a rapid and simple shut-off has to be performed, such as in a water line. Conversely, ball valves have a lower probability of leaking than globe valves. In such a case, which kind of valve is superior? It is different depending on the particular use.

Ball Valve and Globe Valve Selection Criteria

The application’s purpose should be considered when deciding between a globe valve and a ball valve. During the choosing process, the following are the primary considerations that should be taken into account:

Pressure drops:

Because flow passes through ball valves in a straight line, the pressure decreases that they experience are lower.

Flow rate:

Ball valves’ full-bore design makes them attractive for applications requiring a larger flow rate than other valves.

Temperature:

Ball valves perform better in high-temperature environments. They are constructed with strong materials.

Maintenance:

Ball valves are easy to maintain since they need a little oil to remain clean and function properly. Whenever debris builds up, further maintenance is required.

Bottom-line

When it comes to the design of any pipe system, the selection of valves is a vital component. In the oil and gas business, two of the most frequent valves are the globe and the ball valves. Although both valves have advantages, globe valves are more suitable for applications requiring a secure seal, such as those in high-pressure systems. Application areas that need a rapid shut-off, such as emergency shutdown systems, are ideal for ball valves because of their superior performance. If you are searching for a valve that can be used for business purposes, it is important to choose a reliable ball valve manufacturer. Always do thorough research before making any irreversible choices.