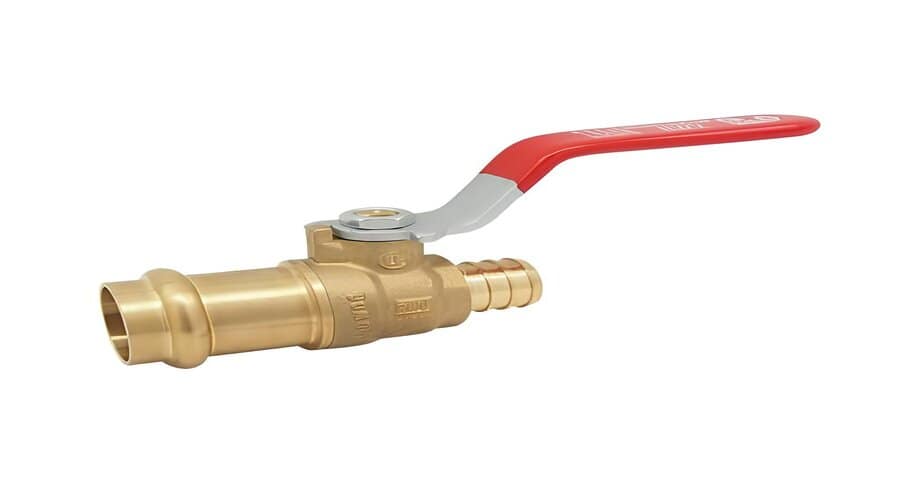

The designers have designed a pex valve to connect with tubing made from crossed-linked polyethylene. It links to PEX pipes and pipes without transition adapters.

This is the significant difference between these valves and regular valves. Apart from this difference, they share remarkable similarities and help many of the same purposes. People often use this shut-off valve for repair operations and maintenance.

PEX-valve tubes and pipes use cross-linked polyethylene as the type of polyethylene. The linked polymers have properties that make them excellent for heating, cooling, and thermal purposes. The cross-linking method improves or adds qualities to the material, making it better for plumbing parts. Three ways exist: A, B, and C. Each has different methods and technologies, creating materials with other properties.

How Does a Pex-Ball Valve Work?

To control the water flow, the pex-ball valve threads onto the end of the pex-pipe shut-off valve pipeline. However, it functions using the handle and the rotary ball contained within.

Close the valve when the handle is perpendicular to the valve’s body. However, when aligning the handle with the valve, water can flow through an open valve.

We utilize the quarter-turn procedure. The handle barrier effectively restricts further rotation of the handle to a maximum of 90 degrees.

Turn the lever to the right to release the valve. The handle connects to the ball, and turning the handle moves the ball. As a result, the water will flow through the spherical opening, aligning with the flow path.

Additionally, rotate the handle counterclockwise to shut off the valve for cross-linked polyethylene. Thus, the ball will reverse direction and clog the sewer.

What Is PEX-Tubing/Piping Material

Three techniques exist for the fabrication of cross-linked polyethylene. Cross-linked polyethylene A, polyethylene B, and polyethylene C are different materials. Each material undergoes further processing, which results in unique properties for each. Because of their specific properties, each material is well-suited for a fantastic set of components and applications.

What Is PEX A:

Using the “Engel” technique, this material is cross-linked. We add peroxides to the polyethylene material before forming it.

This type of cross-linked polyethylene, the most versatile of the three, can meet your home’s water supply plumbing requirements. When exposed to freezing water, it expands the most, making it the most cracking-resistant in cold conditions. It is costlier than options B or C but also easier to deal with.

What Is PEX B

Is pex b pipe expandable? This pex-pipe valve is a material that becomes cross-linked through the silane process, also known as steam or moisture cross-linking. After forming the polyethylene, we execute the previously mentioned procedure.

What Is Cross-linked Polyethylene C:

Cross-linking this substance involves subjecting it to gamma or electron beam radiation. Out of the three cross-linking methods, the method is least frequently used.

PEX Valve Connection Types

Depending on their design, numerous methods exist to connect couplings, tubes/pipes, and valves. It offered the following kinds of connections:

F-1807

ASTM F1807 specifications make these connections. The following are the processes involved in installing valves using a crimp ring and PEX tube/pipe:

- First, you’ll need to slide the crimp ring onto the end of the water shut-off valve.

You must place the union nut over the tailpiece before attaching the tailpiece to the tube or pipe. Upon stopping, insert the valve into the end of the tubing or pipe.

- After slipping the crimp ring over the valve’s ribs, place it over the end of the tubing or pipe and press down firmly.

- Use a crimping tool to close the crimp ring firmly.

- Ensure the crimp is done correctly by using a gauge.

F-1960

- The manufacturing process for these connections follows the ASTM F1960 standard. To install a valve, you need a special plastic and a ring. Follow these steps to complete the installation.

- Attaching the ring to the pipes or tubing made

- Before linking the tailpiece to the pipe, mount the union joint over the tailpiece when installing one.

- Applying the expander tool to the cross-linked polyethylene tubing/piping and ring

- Connect the expanded assembly to the PEX valve by insertion

EVERLOC+

The fabrication process of these connections adheres to the REHAU EVERLOC+® patented system. To install valves with EVERLOC+® compression connections, you need REHAU cross-linked polyethylene tubes/pipes. It would be best if you also had an EVERLOC+® pex compression valve. You should limit component installation to the use of EVERLOC+® compression-sleeve tools exclusively.

Why Should I Choose PEX Valves for My Application?

Almost all industries use valves in residential and commercial applications. Choosing the right type is vital because the applications are critical, and failure could have disastrous consequences. Highlighted below are several factors you should consider when evaluating your valve options.

- Cost

Cost is a significant consideration for almost all purchases. Choose a product that meets your needs and budget. PEX valves connect directly to PEX tubing, saving money and reducing potential points of failure.

- Environment

The environment within an application significantly impacts the performance of a product. Chemicals and temperatures are critical environmental conditions for valves. When fabricating PEX valve assemblies, you should utilize dezincification-resistant (DZR) brass.

Time for installation. The duration of component installation impacts labor costs. You can install PEX valves on tubing without adapters, which makes it faster and simpler than other valves.

To use a PEX valve assembly, choose between cross-linked polyethylene A, cross-linked polyethylene B, or PEX C tubing and pipe. When selecting an option, consider factors like these:

PEX A is more flexible and kink-resistant than PEX B, which is the least flexible and kink-resistant. Fitting materials are more challenging than PEX A, B, and C.

Advantages of PEX Fittings and Valves

Pex valve fittings valves are better and cheaper than copper fittings and last longer. Cross-linked polyethylene is flexible, so you require fewer installation connections than copper pipe and fittings. Because of this, there will be less need for connections, resulting in fewer fixtures and lower labor expenses. Furthermore, a system with fewer connectors reduces the risk of leakage.

Pex Valves Applications

This kind of water valve also exists in applications for hydronic heating systems. However, it warms interior spaces using baseboard heaters or radiators that circulate hot water.

PEX valves have applications in both commercial and residential water supply systems. Pex-water valves regulate the flow of water to fixtures and appliances. It is held in faucets, showers, and bathrooms.

PEX water valves are used in refrigeration systems, specifically chilled water circulation. Furthermore, it regulates temperature and flow in industrial processes and buildings.

It combines cold and hot water to achieve the desired temperature for a given fixture. This could ensure a comfortable and secure water supply.

PEX Ball Valve Types

Pex ball valves are full-port, two-way valves. It has equal-sized crimp-style connectors and a pax 1 4-turn valve on both ends. Plumbing technicians install them in the conduit using crimp or clamp connections.

PEX copper-type valves resemble those described above, except one side is modified to accommodate copper pipe installation. These valves help the conversion between copper and pex shut-off valves. These are frequently employed in conjunction with copper manifolds.

Push to connect fitting valves fitting, referred to as “push fit” valves. It facilitates the installation of a pex shutoff valve without the need for tools or rings. Moreover, they offer a practical way to switch between PEX and copper pipelines.

Lead-free brass pex cut-off valve is utilized for most options in plumbing systems by “low-lead” regulations. Standard brass is less expensive. It is suitable for heating purposes other than beverage preparation.

PEX Stop Valve Uses and Types

After building or building, a stop valve is used to cut off the water supply while fixing or maintaining a plumbing fixture or appliance. Pex stop valves may be either straight or angled.

If the pipe protrudes too far from the wall, install a valve. This valve should have a pipe that enters and exits at right angles. People typically install straight valves where the pipe comes out of the floor because they allow for refined intake and outflow.

Use any tubing or crimp/clamp connection method with the inlet connectors on these PEX valves. Standard braided, metal, or plastic risers of the proper diameters are compatible with outlets.