Description

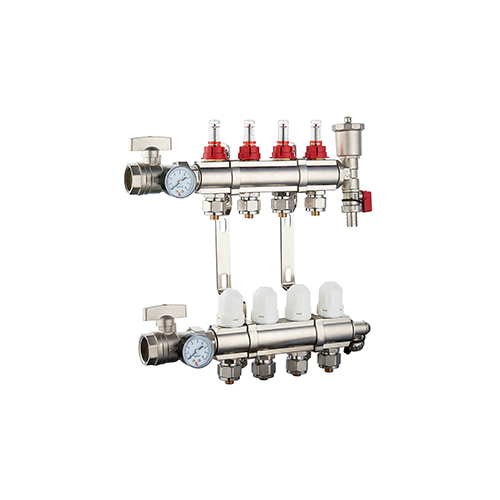

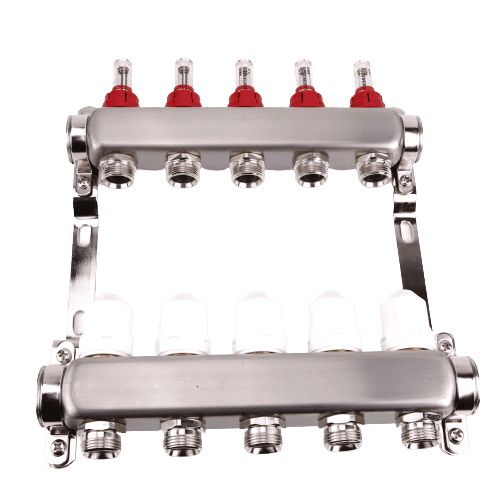

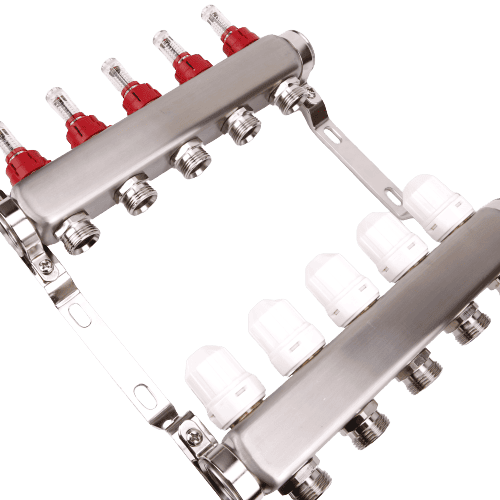

Pex Heating Manifold Stainless Steel

JX-0701

- Stainless steel Manifold

- Stainless steel 304

- Polishing surface treatment

- Operating temperature;-10-110℃

- Working pressure; Max 16 bar

- Connection thread; 3/4″&1/2″ loop

- Hard sealing with a flexible fitting connection.

- Manufactured from corrosion-resistant and durable Stainless Steel to last for life

- Compatible with any type of PEX tubing – no special adapters needed

- Simply mount the manifold on brackets and connect the valves and PEX tubing

- The Manifold connects the heat source – a boiler, heat pump, or other – with the water underfloor heating circuits, regulates the incoming water temperature via the Mixing Unit and distributes this warm water throughout the floor circuits for an energy-efficient heating system.

- Made from High-Quality Stainless Steel to last for life.

- Supply PEX manifold with PEX tubing outlets and adjustable flow meters;

- Manifold flow meters (flow indicators) allow monitoring of GPM (Gallons Per Minute) water flow through individual manifold branches.

- Return the PEX manifold with PEX tubing outlets and balancing (flow adjustment) valves; Balancing valves allow for the adjustment of water flow for each branch independently and help to properly balance the radiant heating system.

- Isolation ball valves with 1″ BSP connections and F° temperature gauges; Ball valves allow for easy service and pressure testing, while temperature gauges help monitor supply and return water temperatures.

- An underfloor heating manifold is a modern solution with a superior heating circuit plumbing system. It makes the perfect comfortable temperature for the home and indoor heating supply. This is a heating device where all supply or return hot water and cold water mix together. It also includes a larger pipe as a part of the heating manifold. This pipe either supplies the tubing with water or returns water to a heat source system. Please Stainless steel manifolds for hydronic underfloor heating systems. This might go in conjunction with a pump/blender unit. You can also couple it with the blended/pumped heat source. Basic Construction Principle of ManifoldThe Manifold comes from pressed stainless steel. After a very stringent testing procedure, they make this. They test every Manifold with 6 bar pressure (typical operating pressure would be less than 3 bar). The Manifold always contains an air vent. You can upgrade it to an automatic version. A fill/drain point with a hose connector comes on both the flow and return bar. Sometimes you can use a pump set unit with a Manifold. The pump can able to rotate through 90 degrees. As a result, it becomes very slim in profile, which can fit into a manifold cabinet. It is possible without the need to amend the unit.There should be an incorporated flow temperature gauge on the flow bar. The blender valve should have a greater temperature range of 25-80 degrees. And this is a bonus for commissioning and initial set-up. It means the systems can run at a low flow temperature. Besides, it won’t threaten sensitive floor coverings too. The size and type of heating manifold depend on the project. It also depends on the number of rooms, flooring, and the kind of underfloor.

Features & Benefits of using Underfloor Heating Manifold

Installation: It is simple to install. It requires the least installation effort. And also easy to maintain.

Comfort: The Manifold system uses radiant heat. It is the most pleasant form of Heating. It gives an even distribution of heat over the whole room.

Space: Manifold system is unobtrusive and space-saving. It utilizes every square meter of floor and wall space. It gives freedom to interior design.

Noise: Generally, radiator systems make sounds. But this heating system runs with no noise.

Health: It reduces house dust mites. Its ideal hot surfaces reduce the risk of burns.

Economy: Manifolds operate at lower temperatures than radiator systems. It makes them especially suitable for condensing boilers. As a result, it reduces energy consumption. It also lowers heat loss from the building structure.

Control: The Heating Manifold system is easy to control. It can self-regulate the temperature. As a result, there happens a small temperature difference between the floor and the air.

Environment: The manifold system is the most suitable to use. It is energy-efficient.

- Components of an Ideal Heating Manifold ModuleFlow Gauge: Indicates the flow rate.

- Pressure Gauge: It measures the pressure during the pressure test.Actuators: They can control individual zones with a room thermometer. One can buy an Actuator with or without switches.

Mixing Unit: It unites water coming from the heating source. It permits the temperature to rise to 60 degrees Celsius. And the lowest range is up to 20 degrees. The Mixing Unit has 3 parts: lower Arm, Upper Arm, and Circulator.

Valves for Isolation and Commissioning: Isolation Valves allow the Manifold for isolation. Commissioning Valves can control the water flow.

Setpoint Controls: They can protect concrete from cracking.

Electronic controls panel: It maintains the temperature of the supply water. The heat source should have three features. Firstly a source that accepts low temperature returns to water. Secondly, a source that has continuous circulation. And finally, a source that has a setpoint control or a reset control.

How to Install a Heating Manifold