Electrical Ball Valve Inquiry

This is an inquiry from the UK in 2019 before COVID-19. The customer asks us if we can provide an electrical and motorized ball valve that works for the heating system.

We got they require a brass check valve and butterfly ball valve as well this time. Ask if we can send out 2 samples/each size; there are only 1/2 inch and 3/4 inch.

We don’t prepare samples the first time. It’s due to the motorized ball valve having 2 working electric voltages One is 220v-230v;24v and 12V, AC and DC are different options.

There are different working conditions.

So, we need to check the applications of the motorized ball valve and other brass valves with the first task.

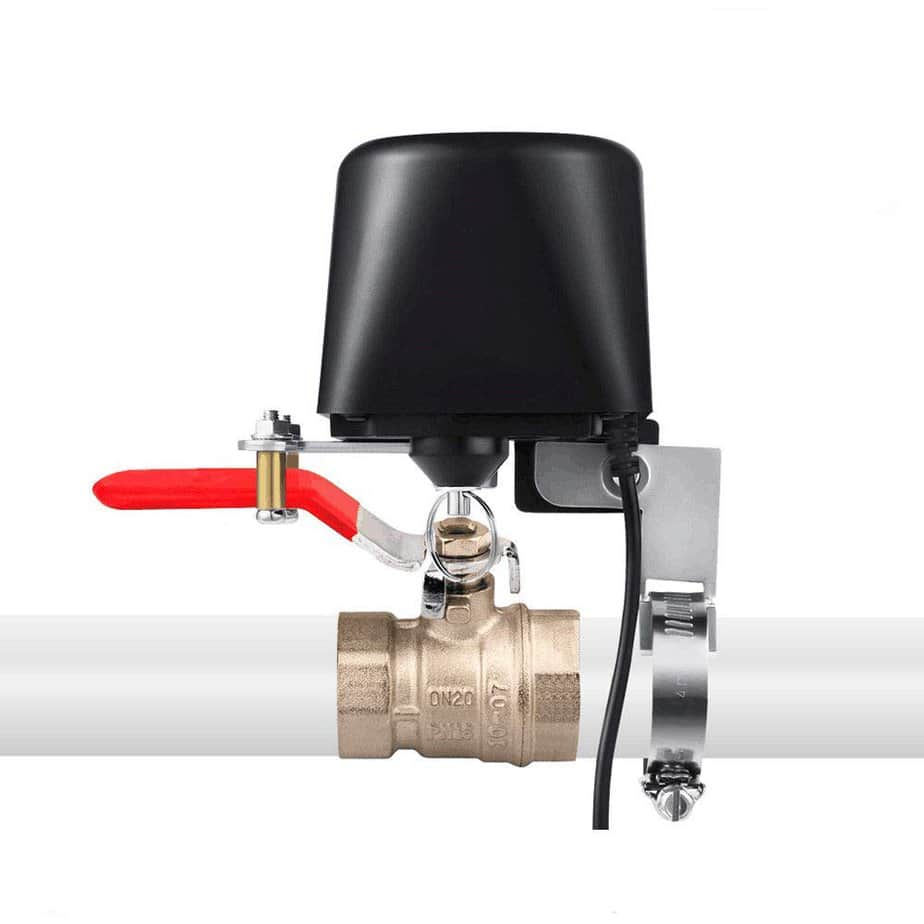

Standard electrical actuator ball valves are applications for air conditioner pipes, heating systems, and water tanks so that we can release the water with a flip of a switch from the driver seat without having to go under the van. It’s for controlling the fluid water automatically shut off and turn on.

We understand that they are using it for water heating systems after communications and research. It can be used in residential and commercial buildings. So we recommended two options motorized ball valve for them.

- There is a normal one with economy type with reduced bore 220V-230V AC. DN20 and PN 16, 3 wires with 2 controls. The functions are the same, and they match the HVAC system as well;

- The other one has a heavy-duty type,1.0MX4 wries with 3-point control, PN16 Running time 33-36 seconds, and ISO5211-F03 valve platform. They are top-rated in Europe.

- The butterfly ball valve and check valve advise a heavy type ball valve with a full port—the ball valve with the aluminum knob, brass ball, and brass stem. We will use CW617N steat of the standard brass; then, it’s better to match the European rules for valves. Vertical spring check valve instead of swing check valve because the applications request the correct one, but we are not sure if using a brass core pin or plastic core pin inside.

We decided to dispatch more samples for confirmation after a few days of communications and video calling with the customer. even though we prefer that Heavy-duty electric ball valve. And full-bore butterfly valve with 400WOG. And full brass vertical spring check valve, because they match a reliable quality with 2 years warranty. But we still try to send economy types for customer’s comparison

Electrical Ball Valve Solution

They tested samples and replied that they selected the heavy one as our prediction one month later.

So we started to talk about pricing and quantity, package, lead time…

We are packing just with a regular white color box with brown cartons with a sticker. Lead time is a 45days. And we gave them a reasonable price, so there are confirmed within one week. But they are not satisfied with our lead time, they need us to produce it within 20 working days, and they need us to provide solutions for the airway, courier, and sea freight details.

We have a meeting for the lead time(production period) and try to solve the issue because 100-10000 units are within the same production period, but the customer required it urgently. Hence, our team led our production manager, coordinator, and QC manager for a support discussion. Finally, we found a solution because of one customer from Ireland. Still, the PO is currently under production, so we contacted the client and agreed to let us ship out 200pcs for the other customer and make it for replenishing it later, so we solved the 20 days lead time problem.

Then go ahead for the next one.

There are three ways to ship the customer.

- Sea freight $450 45 days Customer takes cargo from the seaport

- Airy way $900 10 days Customer takes products from the airport.

- DHL $1300 7 days Door-to-door service (Same as sample)

We are taking a few days to confirm these details. The customer changed the quantity 3 times, so other information, package, and cost were amended within 12 hours each time and gave more information and specifications answer to them.

Electrical Ball Valve System Process

They chose 50% with sea freight and the balance shipped by DHL courier, so we adjusted some plans for it.

We got the 30% advance deposit in early November, so we made a plan for the project immediately, and the sea freight and courier cost isn’t stable due to COVID-19. It’s getting high day after day, so we don’t like any mistake and delay. Our valves were ready within 18 days, and we notified the customer that we were preparing documents for loading and DHL courier; even though we paid more cost for the logistics freight, we were happy to support the new customer in the final.

Why can we get the valve order?

- We have more experience and professional technical ability to understand the customer’s request. Because the motorized ball valve is currently hot sales, it can automatically control water rather than manually handle it. Even though it’s more costly than a typical manual operating ball valve, it’s convenient. This is a spare part for a heating system and air-conditioning; it takes 1-2% of the project’s budget, but it’s innovative and ideal for intelligent operations.

- Long-time free warranty, no need to worry about the quality, and can sleep well, the cost reduces maintenance costs.

- Easy installation because we provide specifications, a step book, and videos, even for an online tutorial guide if you have any questions. It’s easy to use.

- Documents paperwork, customs clearance, logistics, sea freight, courier, and airway are rich experiences and friends for help.

- The electrical ball valve is hot sales with 5 years in Europe. We are confident that we will pass all of the tests. Heavy body with the original brass, ball, and stem,2 way and 3 way both are okay, from 1/2”,3/4”,1” and 11/4”, and the actuator’s using a synchronous machine which drives the gears steady, It’s suitable the control of water system; Electric and manual both operation are available with position indicator.

The exact specifications of electric actuators can vary significantly based on the manufacturer, model, and intended application. However, when discussing electric actuators, especially for valve operation, there are some common specifications you would typically look out for. Here’s an outline of such specifications:

UK Standard For Electric Valve

Voltage:

- Operating Voltage: The voltage required to operate the actuator. Typical values might be 12V, 24V, 110V, or 230V AC/DC.

Power Consumption:

Wattage: The amount of electrical power the actuator consumes during operation.

Speed:

- Operating Speed: The speed at which the actuator can open or close a valve, often measured in seconds per 90-degree rotation or mm/second.

Duty Cycle:

- Percentage: The duty cycle denotes the percentage of time the actuator can remain operational before requiring a rest period to prevent overheating.

Torque:

- Measured in Newton meters (Nm): The force the actuator can exert to open or close a valve.

Control Options:

- Modulating or On/Off: Whether the actuator is simple on/off or can modulate the valve position based on the input signal.

- Signal Input: The type of signal used to control the actuator. common types include 4-20mA, 0-10VDC, or digital signals.

Environmental Ratings:

- Ingress Protection (IP) Rating: Indicates how well the actuator is protected against dust and water ingress, e.g., IP65 IP67.

- Temperature Range: The range of operating temperatures within which the actuator can function reliably.

Enclosure Material:

- Material Type: Common materials include plastic, aluminum, or stainless steel, which affect the actuator’s durability and resistance to corrosion.

Mounting:

- Mounting Options: How the actuator can be mounted to the valve and any applicable standards such as ISO 5211.

Fail-Safe Features:

- Fail-Safe Operation: Whether the actuator has a fail-safe mode that can either open or close the valve in the event of a power failure.

Feedback:

- Position Feedback: Whether the actuator provides feedback on the valve’s position, and the type of feedback (e.g., visual indicators, electronic signals).

Certifications:

- Compliance Certificates: Certifications indicating compliance with industry standards or regulations.

Connectivity:

- Communication Protocol: Such as Modbus, HART, Profibus, or others for integration into control systems.

Each of these specifications can impact an electric actuator’s performance, compatibility, and suitability for a particular application. When selecting an electric actuator, it’s crucial to ensure that the specifications align with the requirements of your application and the regulations of the UK market, especially in terms of electrical standards and safety.

Electrical Ball Valves: Steering Flow Control in the UK

The terrain of plumbing and industrial applications is fast-evolving with the adoption of innovative technologies, among which electrical ball valves take a prestigious position due to their efficiency and ease of control. Specifically, in the UK market, where strict regulations and standards govern the sector, these valves have become an integral part of modern systems.

What are Electrical Ball Valves?

Electrical Ball Valves are a type of valve that utilizes an electric motor to control the flow of liquids or gases within a pipe or duct. The core component is a spherical disc, the orientation of which determines the flow status – open or closed.

Operational Mechanism:

- Rotary Motion: Upon receiving an electrical signal, the motor activates, rotating the ball to the desired position (open or closed).

- Sealed Tight: The valve seals tight, preventing leakage and making it a reliable option for various applications.

Why are they preferred in the UK?

- Precision Control: Offers precise control over flow rates, which is crucial in many industrial and commercial settings.

- Energy Efficiency: Consumes less power compared to other electrically operated valves.

- Compliance with Regulations: Adheres to the strict plumbing and electrical standards set forth by UK authorities.

Diverse Applications:

- Water Treatment Plants: Crucial for controlling the flow of water and treatment chemicals.

- Heating Systems: Control the flow of hot water or steam in commercial and residential heating systems.

- Industrial Processing: A linchpin in myriad industrial processes requiring precise flow control.

Compatibility and Installation:

- Ease of Installation: Generally easy to install and integrate with existing electrical control systems.

- Compatibility: Compatible with most of the UK’s electrical systems and compliant with local electrical codes.

Product Availability and Support in the UK:

- Wide Range: A plethora of options available catering to different requirements and specifications.

- Local Support: Many suppliers provide local support and after-sales service, ensuring a seamless user experience.

Customization and Innovation by Plumberstar:

Plumberstar ensures the provision of highly efficient and reliable valve solutions to wholesalers, middlemen, and factories. The tailor-made valves, marked by their high quality, excellent performance, and ability to handle large order quantities, carve a niche in precisely meeting the client’s needs.

Conclusion

The UK’s regulatory landscape and the growing emphasis on energy efficiency and precise flow control catalyze the demand for electrical ball valves. Plumberstar, with its commitment to quality and innovation, stands at the forefront in meeting this demand, thereby fostering a long-term partnership with its clients and contributing significantly towards modernizing the UK’s plumbing and industrial sector.

The convergence of robust design, ease of control, and adherence to stringent standards makes electrical ball valves a preferred choice, underlining their pivotal role in steering the UK towards a future of enhanced operational efficiency and sustainability.